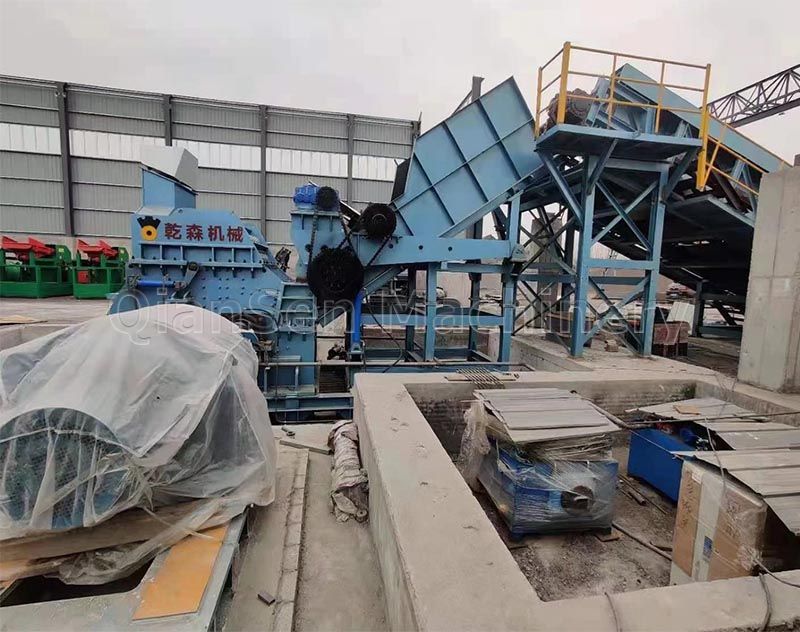

The Qiansen car recycling plant uses specially designed heavy duty metal shredders for initial shredding and heavy duty hammer shredders for further processing. This is followed by a dust removal system to remove dust, a powerful magnetic separator to separate ferrous metals and a high efficiency eddy current separator to remove non-ferrous metals.

The Qiansen car recycling plant uses specially designed heavy duty metal shredders for initial shredding and heavy duty hammer shredders for further processing. This is followed by a dust removal system to remove dust, a powerful magnetic separator to separate ferrous metals and a high efficiency eddy current separator to remove non-ferrous metals.

*Optimal shredding: High efficiency scrap crusher system cuts end-of-life cars into small pieces.

*Long service life: each component is made of reliable materials to ensure sustainable production.

*Low Power Consumption: Patented technology keeps the power required to run the machine low, reducing investment and running costs.

*Maximum throughput: High-precision sorting system provides higher capacity and better quality.

Traditional large shredders are increasingly being replaced by medium-sized plants and end-of-life vehicle shredders from Qiansen. The reasons for this are easy to understand: medium-sized end-of-life vehicle recycling plants are more efficient, require lower capital investment and have lower operating costs. In addition, end-of-life vehicles can be processed directly at the source, resulting in significant savings in transportation costs.

When shredding end-of-life automobiles, it is important that the vehicles are pre-shredded before they are fed into the hammer mill. Pre-shredding offers numerous advantages; it ensures that the hammer mill operates as efficiently as possible, increasing output by up to 60% while significantly reducing wear and tear on the hammer mill and energy costs. In addition, the pre-crushing process filters out non-crushable items and neutralizes any potentially explosive items, such as partially filled fuel and gas tanks.

1.Are you trading company or manufacturer?

We are the manufacturer, and We guarantee that under the premise of the same technical parameters and quality, we provide the most appropriate price.

2.How long is the delivery time?

For standard machines, it would be about 30 days; For non-standard machines and customized machines according to clients specific requirements, it would be about 45 days.

3.How to pay to you ?

We can negotiate about payment. Generally speaking, our practice is:T/T in advance. We can accept 30% deposit , and balance paid to us before delivery.

4.Where is your factory located? How can we visit there?

Our factory is located in Xinji City, Hebei Province, China, you can fly to Shijiazhuang Zhengding international airport or Beijing Capital International Airport or Shanghai Pudong International Airport,then we pick you by car.Welcome to our factory at any time.

5.How does your factory do regarding quality control?

we are the manufacturer of this kind of shredder for more than 10 years,our customers all over the world, we have rich experience on production and R&D,: All products have to pass strict inspection before delivery. We have gained ISO9001:2008 authentication and Eu CE certification,if you need other certificate and quality control,please contact us.

6.Do you have inspection procedures for machines?

100% self-inspection before packing

7.All products can be customized?

All products can be customized by our team of professional designers.

8. How can i get the after-service?

A. We provide one year guarantee and lifelong maintenance.

B.We will send you the spare parts by free if the problems caused by us.

C.If it is the men-made problems,we also send the spare parts,however it is charged.

D. Any problem, you can call us directly.Anna:86 15930888103(WhatsApp/Wechat/)

| Model | Type of main engine | Feed Opening Width(mm) | Main Motor Power(kw/HP) | Feed Quantity(T/H) |

| PSX-450 | PSJ4865 | 1600 | 450KW/610HP | 8-10 |

| PSX-560 | PSJ4865 | 1600 | 560KW/750HP | 10-12 |

Metal Recycling: The primary application of metal recycling shredder is in the metal recycling industry. They are used to process and recycle various types of scrap metal, including ferrous metals like steel and iron, as well as non-ferrous metals like aluminum, copper, and brass. Shredders break down large metal items into smaller pieces, making it easier to sort, separate, and recycle different types of metals.

Automotive Industry: Steel scrap shredder play a vital role in the automotive industry for recycling end-of-life vehicles (ELVs). ELVs contain various metal components such as car bodies, engines, transmissions, and other parts. Steel scrap shredder machine are used to break down and shred these components into smaller pieces for metal recovery and recycling.

Electronics Recycling: Electronic waste (e-waste) contains valuable metals that can be recovered and recycled. Waste scrap metal shredder are used to shred and process e-waste, including computers, laptops, smartphones, and other electronic devices. This enables the extraction and recovery of metals like copper, gold, and silver from electronic components.

Construction and Demolition Waste: Construction sites and demolition projects generate a significant amount of metal waste in the form of structural components, pipes, wiring, and other materials. Industrial steel shredders are utilized to shred and process this metal waste, making it suitable for recycling and reducing the environmental impact of construction and demolition activities.

Manufacturing and Foundry Operations: Manufacturing facilities and foundries generate metal waste as a byproduct of their production processes. Scrap metal recycling line are used to shred metal scrap, excess materials, and rejected products, allowing for efficient recycling and reintegration of the metal into the manufacturing cycle.

Municipal Solid Waste Management: Steel scrap shredder can be employed in municipal solid waste management facilities to shred bulky metal items found in the waste stream. Shredding these items reduces their volume, improving waste compaction and storage. The shredded metal can be further processed for recycling, reducing the environmental impact of metal waste disposal.

Environmental Cleanup and Remediation: Recycling scrap metal shredder are utilized in environmental cleanup and remediation efforts, particularly in cases of metal-contaminated sites. They are used to shred and process contaminated metal debris, facilitating the removal and disposal of contaminated materials.

Resource Recovery Facilities: Resource recovery facilities focus on extracting valuable materials from different waste streams. Metal scraps shredder machines are used to shred and process metal-containing waste materials, such as appliances, machinery, and equipment, allowing for the recovery of metals for recycling purposes.

Waste Car Body Shredder Line

Waste Car Body Shredder Line

Waste Car Body Shredder Line

Waste Car Body Shredder Line

Waste Car Body Shredder Line

Waste Car Body Shredder Line

Copyright © Xinji Qiansen Environmental Protection Technology Co.Ltd All Rights Reserved | Sitemap | Powered by