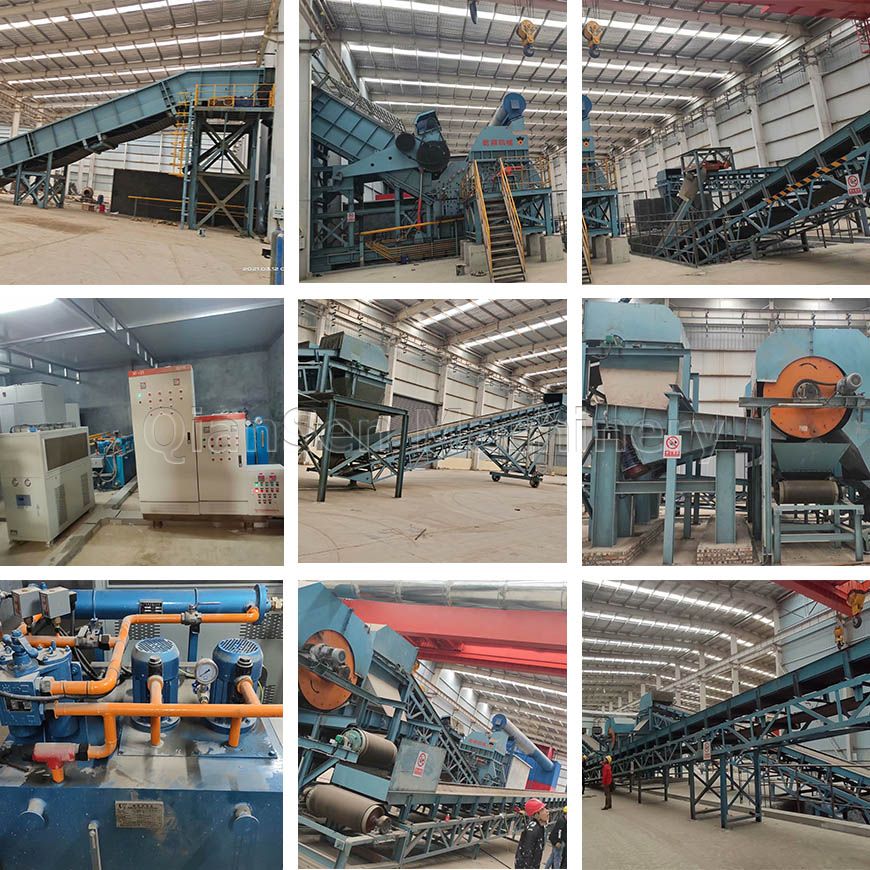

The main motor power of scrap metal shredder mainly include:2240KW-3150KW

PSX2240-3150KW whole line layout length: 82m;

The widest point of the shredder: 23m;

The highest point of the shredder: 8m

Automotive shredders are used for heavy duty metal recycling of cars and vehicles. The twin shaft shredder body is mounted at an angle on a sturdy support structure. Material is loaded into the hopper and conveyed to the cutting shafts by means of a hydraulic feed pusher, which facilitates feeding and dismantling, optimizes efficiency and prevents the "flotation" effect. The movement of the pusher and the quick discharge is managed by a hydraulic control unit mounted under the support frame of the pusher.

All four motors are powered by inverters that manage the speed and power of the motors

Strong, very thick monolithic elements in the pulverizer body

Large welded steel loading hopper

The operating cycle is fully controlled by a PLC

In the market for a rugged new industrial shredder? Is your current shredder aging and starting to deteriorate? Does it lack solid design and reliability? Whatever your industrial shredder situation, Qiansen Technology Solutions can help.

Metal shredding is a tough, difficult process that requires equipment that can withstand extreme stress. The ruggedness and longevity of your shredder can make or break your profits. We offer complete design and integration of shredders and separation systems, with a focus on major component analysis for robust upgrades.

Each solution is tailored to your company's specific needs with long-term quality in mind.

1. Our company implements tracking service for products. Pre-sale, sale and after-sales service for customers.

Pre-sales: guidance on equipment layout and equipment foundation;

On sales: guidance on the production, delivery, installation and commissioning technical services of the equipment;

After-sales: Customer daily maintenance, safety production and other services to ensure the normal operation of the equipment.

2.The warranty period for the equipment is 18 months after the arrival of the goods or 12 months after the acceptance (whichever comes first). During the warranty period, the user's fault feedback will be answered within 4 hours.Within China arrived at the customer site within eight hours, other countries to arrive at the customer site within 72 hours.

A.We will send you the spare parts by free if the problems caused by us.

B.If it is the men-made problems,we also send the spare parts,however it is charged.

C.About the purchased parts,Such like:Siemens(motor),SKF(bearing),Rexroth,They are multinational company, and they will have after-sale service points in your local , So you can enjoy global warranty service.

D.The daily loss of equipment provides customers with original parts and processing drawings, which is convenient for customers to choose.

5.Any problem, you can call us directly.

A.we will guide your engineer through the whole installation and debugging process by phone or video;It is free of charge.

B.If you need our staff to go to your site to install, is charged.

1.Are you trading company or manufacturer?

We are the manufacturer, and We guarantee that under the premise of the same technical parameters and quality, we provide the most appropriate price.

2.How long is the delivery time?

For standard machines, it would be about 30 days; For non-standard machines and customized machines according to clients specific requirements, it would be about 45 days.

3.How to pay to you ?

We can negotiate about payment. Generally speaking, our practice is:T/T in advance. We can accept 30% deposit , and balance paid to us before delivery.

4.Where is your factory located? How can we visit there?

Our factory is located in Xinji City, Hebei Province, China, you can fly to Shijiazhuang Zhengding international airport or Beijing Capital International Airport or Shanghai Pudong International Airport,then we pick you by car.Welcome to our factory at any time.

5.How does your factory do regarding quality control?

we are the manufacturer of this kind of shredder for more than 10 years,our customers all over the world, we have rich experience on production and R&D,: All products have to pass strict inspection before delivery. We have gained ISO9001:2008 authentication and Eu CE certification,if you need other certificate and quality control,please contact us.

6.Do you have inspection procedures for machines?

100% self-inspection before packing

7.All products can be customized?

All products can be customized by our team of professional designers.

8. How can i get the after-service?

A. We provide one year guarantee and lifelong maintenance.

B.We will send you the spare parts by free if the problems caused by us.

C.If it is the men-made problems,we also send the spare parts,however it is charged.

D. Any problem, you can call us directly.Anna:86 15930888103(WhatsApp/Wechat/)

Xinji Qiansen Machinery has all kinds of CNC large processing equipment and welding equipment more than 100 sets, is an integrated CNC blanking, welding, machine tool processing, assembly and debugging as one of the comprehensive machinery manufacturing enterprises. The company was formerly a large metallurgical equipment manufacturing enterprise, with strong technical base, processing capacity, perfect R & D, manufacturing, sales team, since 2000 combined with the United States, Germany, Japan and other national technology committed to R & D, manufacturing scrap processing equipment, and successfully produced 160 horsepower - 10,000 horsepower scrap crushing production line, the company has been Hebei Iron and Steel Group stone home Zhuang Iron and Steel Co., LTD., Tangshan Jinma Iron and Steel Group Co., LTD., Wu 'an Xinghua Iron and Steel Company and the national scrap processing base, etc., provide more than 100 scrap crushing production lines with high quality, high efficiency and reliable performance. At the same time, we also design perfect dismantling and crushing schemes for scrapped motor vehicles, special crusher for machine aluminum, broken bridge aluminum and daily miscellaneous aluminum, nonferrous sorting equipment and layout scheme for customers. LX-75 filter crusher, fire iron crusher, ZT-45 paper crusher, etc., all the time, dry Sen machinery continues to strengthen the quality control concept, has obtained ISO9001 quality management system certification, ISO14001 Environmental Management system certification certificate,ISO45001 Occupational Health and safety management system certification certificate.

Model | Type of main engine | Feed Opening Width(mm) | Main Motor Power(kw/HP) | Feed Quantity(T/H) |

| PSX-2240 | PSJ80104 | 2500 | 2240KW / 3000HP | 40-50 tons/hour |

| PSX-3150 | PSJ88104 | 2500 | 3150KW / 4000HP | 70-100 tons/hour |

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Automobile Shell Crusher

Copyright © Xinji Qiansen Environmental Protection Technology Co.Ltd All Rights Reserved | Sitemap | Powered by